- en

- fr

Reactor pool liners

Cegelec CEM designs, builds and installs pool liners in compliance with the construction codes.

The liners of nuclear pools are made of stainless-steel sheets welded together, and must guarantee complete leak tightness of the pool during normal and accident operation.

Beyond their large dimensions, which in themselves require high standards of design, assembly and welding, the metal reactor pool liners must be able to withstand, during construction and throughout their life cycle, the significant mechanical stresses to which they will be exposed:

- Geometric accuracy

- Temperature increases and thermal cycling

- Resistance to pressure

- Major stresses in the event of an earthquake

- Resistance to borax

Since 2010, Cegelec CEM has held the contract for a work package covering the design, construction and installation of nine pools and the associated equipment, in accordance with the RCC-MX and MRX construction codes:

Since 2010, Cegelec CEM has held the contract for a work package covering the design, construction and installation of nine pools and the associated equipment, in accordance with the RCC-MX and MRX construction codes:

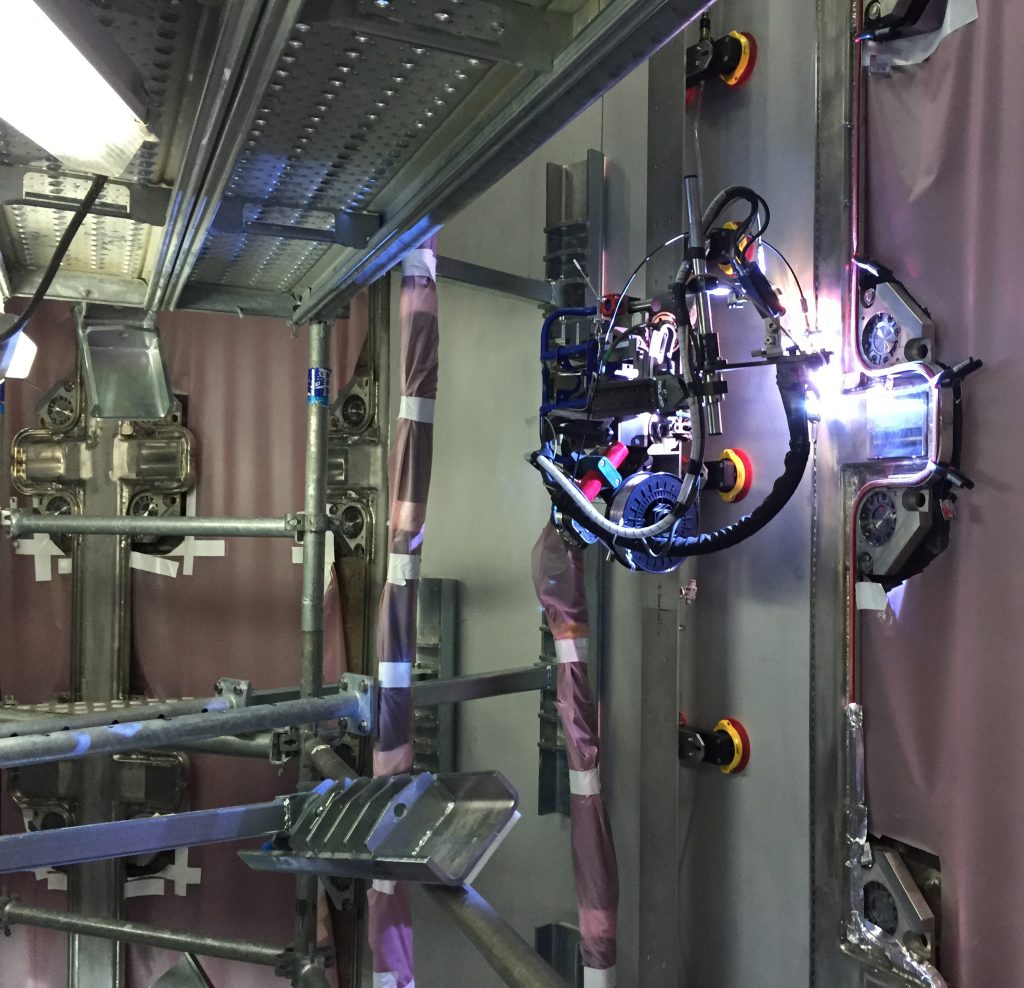

- Development of an all-position automatic machine for site welding

- Qualification and compliance with RCC-MX code criteria

- Development of ultrasonic testing on thin stainless-steel measuring 3.4 and 6 mm

- Lining of nine pools in reactor and auxiliary buildings (tubular structure, liner sheets, second-phase concrete, fittings, etc.)

- Underwater transfer airlock with two doors

- Seven sluice gates

- 29 reactor pool penetrations, some of which with N1 ESPN pressure classification